Solutions for DK PIP Board Book Punching

Background :

The traditional single-page punching machine is a man with one machine production mode, for a single book with multiple page punching needs, it is necessary to correspondingly increase the punching machine and staffing, there is a waste of human resources and the problem of low production efficiency. The purpose of this case is to introduce our automation transformation of the traditional punching machine production mode, and the significant effect brought by the transformation.

Solution: Automation transformation program

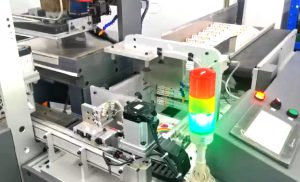

For the problems of the traditional punching machine, we have adopted an automation transformation program to integrate 14 single page punching machines by connecting them to realize batch punching production. The specific program is as follows:

- Connect 14 punching machines into one production line to realize batch punching production.

- Introduce automatic feeding system to reduce manual intervention and improve production efficiency.

- Introduce automatic control system to realize intelligent management and monitoring of punching machine operation.

Effect:

Through the implementation of the above automation retrofit program, we have achieved the following significant results:

| Tradition | Improvement |

Employment | 12 people+6 people | 2.5 people |

Efficiency | 5000 books*12pages | 3000books*12pages |

Time | 10H | 10H |

Quality | 1. Manual feeding, safety hazard; 2. Beer cutting position is not stable, it will shift back and forth; 3. Use more people | 1. Mechanical hand feeding, more safety; 2. Mechanical hand feeding, the depth of the position is fixed; 3. Fewer people, sustainable |

Summarize and Prospect

Through this punch press automation transformation, we have successfully solved the problems of human resource waste and low efficiency in the traditional punch press production mode, and achieved significant improvement results. In the future, we will continue to explore the application of automation technology to continuously improve production efficiency and product quality, and provide cost-saving support for our customers in the market competition.